This department is Top!

Schrijf hier uw tekst

Schrijf hier uw tekst

How did you end up at Lentink? Was technology already advertised then? From school or else?

How did you end up at Lentink? Was technology already advertised then? From school or else?Through a company in the area I ended up at Lentink on a temporary basis. After starting a one-year contract, I then got a permanent contract.

I wanted to work and learn and it is a top company. But then you must first have seen it from the inside. Oh yes, now you can also see it on the outside through the new facade and color scheme and so on.

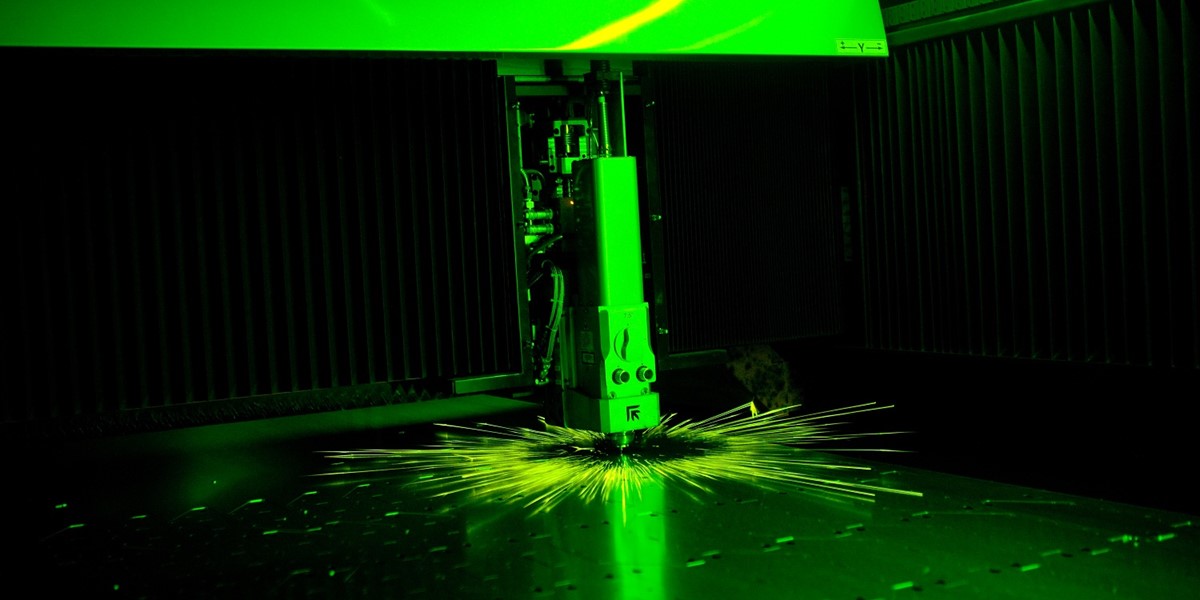

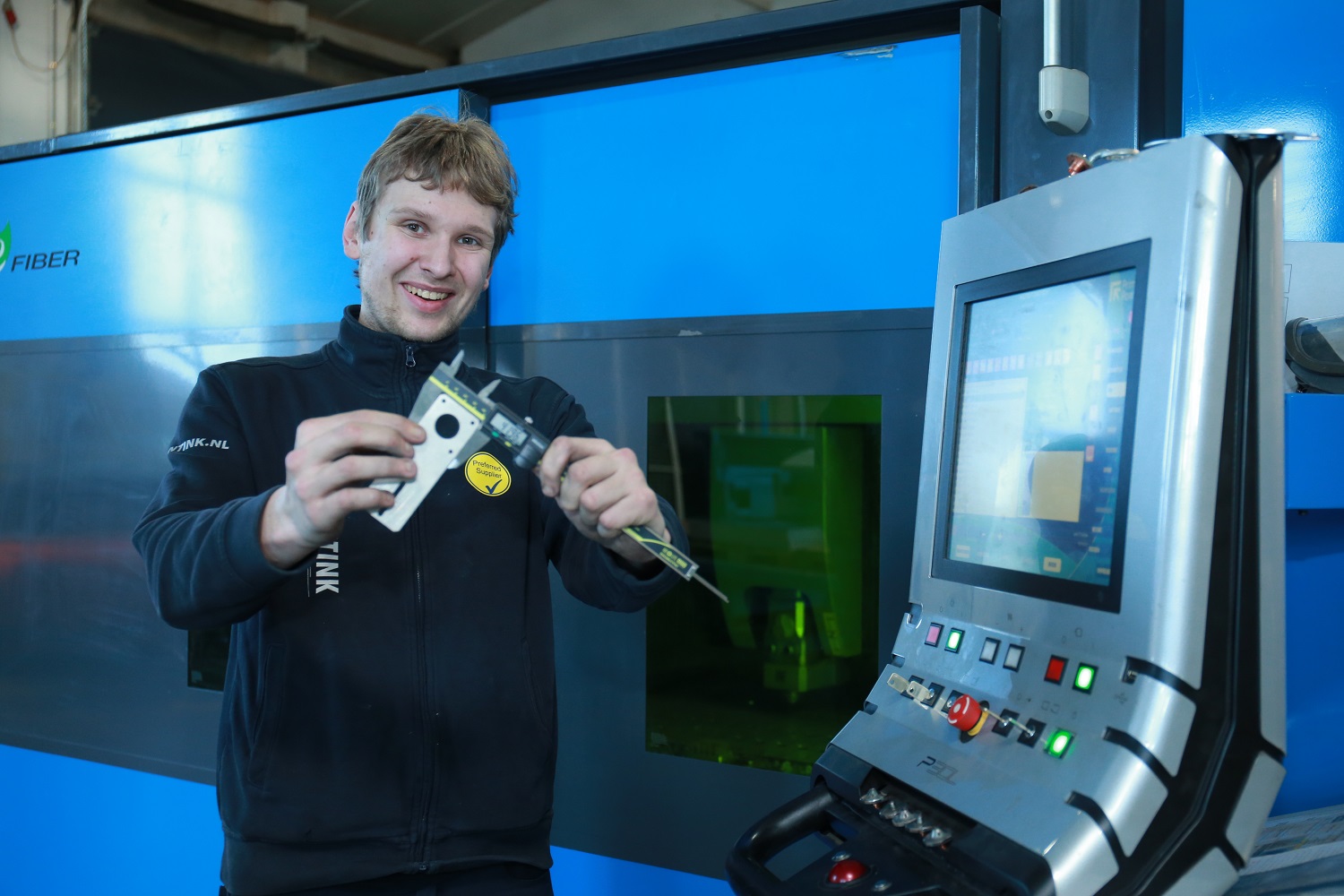

Punching and laser cutting machines including CNC programs & writing the necessary work preparation. I am still learning on the job and go to school for half a day each week.

How do you like your work? Do you like the technique?

How do you like your work? Do you like the technique?Certainly it is here to my opinion the place to be.

Metal is my hobby, also at home. I'm working on everything that has to do with metal.

Nice cozy workplace, with nice colleagues. At Lentink you will never be bored, there is always something exciting to do with the necessary technical challenges. It is never the same here.

Good atmosphere, everything is negotiable with many new ideas & solutions.

What are your personal interests and hobbies outside the work?

What are your personal interests and hobbies outside the work?My interests lie in building corso cars for Lansink Bluiminck and furthermore working on computers and electrical engineering.

Well, actually a lot, but not something that is interesting for others. Oh yes, yes;

At the Technishow we saw a machine that we can use for Lentink we found in our department. We presented this to Daniël (dir) and now the machine is there. Our management has a listening ear for the employees and their ideas, that was before Daniël became owner quite different.

Actually, everything goes as I could wish right now, listen to your people and keep it up I would say to Daniël.

Absolutely, we are always working more efficiently with regular introduction of innovations. I'm already looking forward to the next coming Technishow.

Hats off to Lentink, on to the next 60 years. For myself, wider deployment and perhaps manager in the future.

Don't let people underestimate technology, it is very broad and you can go in many directions within a large metal company such as Lentink. Don't be afraid of the difficulty if you really want to achieve something and you want to earn a good living. Then choose metal. You are guaranteed to get a job in a short time.